Project: Reliability Engineering

Topic: Improvement of the lifetime of a loudspeaker for a global tier 1 automotive supplier

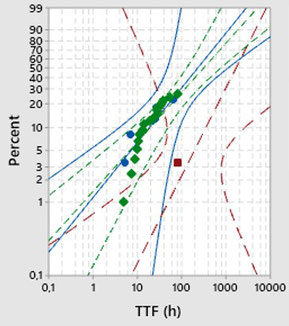

Method

- Development of lifetime tests to characterise the life distribution and reproduce the failure mode observed in the field

- Determination of the failure mechanism by analysis of the vibration dynamics of the membrane and voice coil

- Optimisation of the material parameters of a damping element

Results

- Increase of the lifetime by a factor of 4

- Thus solving a long lasting quality issue and ensuring continued product success on the market

Project: Cost Engineering

Topic: Build up cost engineering practice in electronics department of global automotive tier 1 supplier

Method

- Cost model development for high-cost products and BoM components

- Benchmark analyses covering materials, components and manufacturing

- Analysis of cost breakdowns from supplier quotes and identification of gaps to best cost practices

- Analysis of customer’s product designs and manufacturing process flows and identifaction of saving potentials

Results

- Saving potential identified: > 15 Mio USD / year, based on cost models created and confirmed by benchmark results

Project: Thermography

Topic: Characterisation of the temperature decay of electronic components following high and low temperature storage

Background and Method

- Certain product parameters are to be determined at high and low temperatures while their measurement directly in the climate chamber is not possible

- In practice, the parameters are measured directly following the temperature storage - at unknown component temperature

- By knowledge of the temperature decay curve of the components the temperature in the instant of parameter measurement can be deduced

- Temperature decay curves have been measured by a thermographic camera

Results

- The components' temperature decay is a rapid process and follows an exponential model

- For example, 15 seconds after removal from the climate chamber, the component temperature differs by 30°C from the storage temperature